Evaporative cooling; an alternative for Smart Cities

Given your interest we transcribe here the article published in Caloryfrio.com.

The demand for electricity in Spain remains on the rise, increasing every year. The air conditioning is one of the main responsible for this high consumption. The demand for industrial and commercial cold also contributes significantly. This circumstance makes it possible to claim the technology of evaporative cooling as a fundamental saving factor, especially when compared with alternatives such as air cooling.

Smart Cities or smart cities take sustainability as a starting point to develop a concept of city capable of meeting the needs of institutions, companies and citizens in all aspects, including economic and environmental; as well as to improve the distribution of resources through systems of energy saving, lighting or water distribution. The efficient use of air conditioning systems is a priority in this context and it is precisely at this point that evaporative cooling equipment enters the scene, capable of favoring energy saving with maximum environmental respect.

The energy consumption on the rise

According to the data supplied by Red Eléctrica de España (REE), the peninsular demand for electric power in 2017 was around 252,755 GWh, a figure 1.6% higher than that recorded in the previous year.

The same source provides that, if the consumption in January 2018 is compared with the same period of the previous year, of the five activities with the highest electricity consumption, the demand for metallurgy fell by 1.3%, the chemical industry by 7, 7%, the manufacture of other non-metallic mineral products increased by 7.8%, the food industry by 2.6% and that of paper by 3.5%. On the other hand, the activities that contributed most to the growth of the consumption of the large companies were the capture, purification and distribution of water -with an increase of 30.5 %-, the manufacture of other non-metallic mineral products (7.8% ), coking and refining of petroleum (13.6%), the supply of electrical energy, gas, steam and air conditioning (12.8%) and the food industry (2.6%).

To these circumstances, we must add the fact that different reports show that Spain is far from achieving the desirable goals in terms of energy savings in construction and rehabilitation. The data that is offered is of concern and the adoption of measures to reduce consumption is a priority, especially considering that buildings are responsible for 31% of energy consumption.

Evaporative cooling and energy saving: evolving towards Smart City

The cold intervenes in the manufacturing processes of the aforementioned industrial sectors and the production of this cold requires, in turn, electrical energy. In fact, maintaining the correct temperature of fluids or rooms within these industries has a huge impact on the profitability of the plants. The processes of handling and manufacturing of finished products are long and require some type of cooling and / or heating.

At a time when energy efficiency is not only a social responsibility, but also an economic necessity, in addition to being legal in order to comply with international agreements to reduce CO2 emissions, consumption data acquire special relevance and allow us to claim Evaporative cooling technology as a fundamental saving factor, especially when compared with other alternatives such as air cooling.

Operating principle

Evaporative cooling is a natural process that uses water as a refrigerant and is applied to the transmission of excess heat from different processes and thermal machines to the atmosphere. This technology, used in refrigeration and air-conditioning systems with water condensation, contributes to the reduction of the greenhouse effect by limiting indirect CO2 emissions, thanks to the savings in electrical energy consumed and directly, due to the lower risk of gas leaks refrigerants when working the facilities with relatively lower pressures.

The reduction of energy consumption and gas leakage is achieved for two reasons: the efficiency of the process and the high energy efficiency it offers:

.- The efficiency is given because, the greater the efficiency of the industrial process, the lower the amount of energy that is lost and the easier it is to get rid of residual heat.

.- The high performance is derived from the fact that evaporative cooling is an appropriate cooling system to be incorporated into indirect systems. The possibility of getting water cooling temperatures in our climate zone of up to + 25 ° C or lower, allows the use of intermediate heat exchangers, which means that the processed fluid can be cooled in a closed circuit up to 30 ° C or less.

Likewise, the indirect greenhouse effect produced by the thermal power station in charge of generating said energy is lower when a lower energy consumption occurs. Consequently, with this equipment, a lower cost is obtained for CO2 emission rights.

In the same line, the condensation in the refrigeration and air conditioning installations can be carried out at an adequate temperature so that the pressure in the high sector of the refrigeration circuit is much lower, reducing the risk of refrigerant leaks and the impact direct potential.

On the other hand, when the condensation temperature decreases, the consumption of the electric energy necessary to operate a refrigerating machine, with the same performance as that condensed by air, can be reduced from 20 to 80 percent, and even more.

Keep in mind that, in addition to the savings achieved as a result of the reduction of the condensing temperature, only a quarter of the air is needed, when compared to an air cooling equipment, so the power consumption of fan motors It is very inferior.

Conclusions

In the so-called Smart Cities or Smart Cities, refrigeration is one of the elements that can contribute the most to increasing energy efficiency rates and minimizing environmental impact, thus contributing to this concept of sustainability that is so persecuted.

In this context, the use of commercial and industrial facilities that offer a low TEWI index and bet on the use of natural refrigerants -as is the case of water- with minimum values in CO2 emissions is promoted. Evaporative cooling equipment – towers and condensers – respond to all these needs.

Article made by Manuel Lamúa, gerente de AEFYT – Asociación de Empresas de Frío y sus Tecnologías

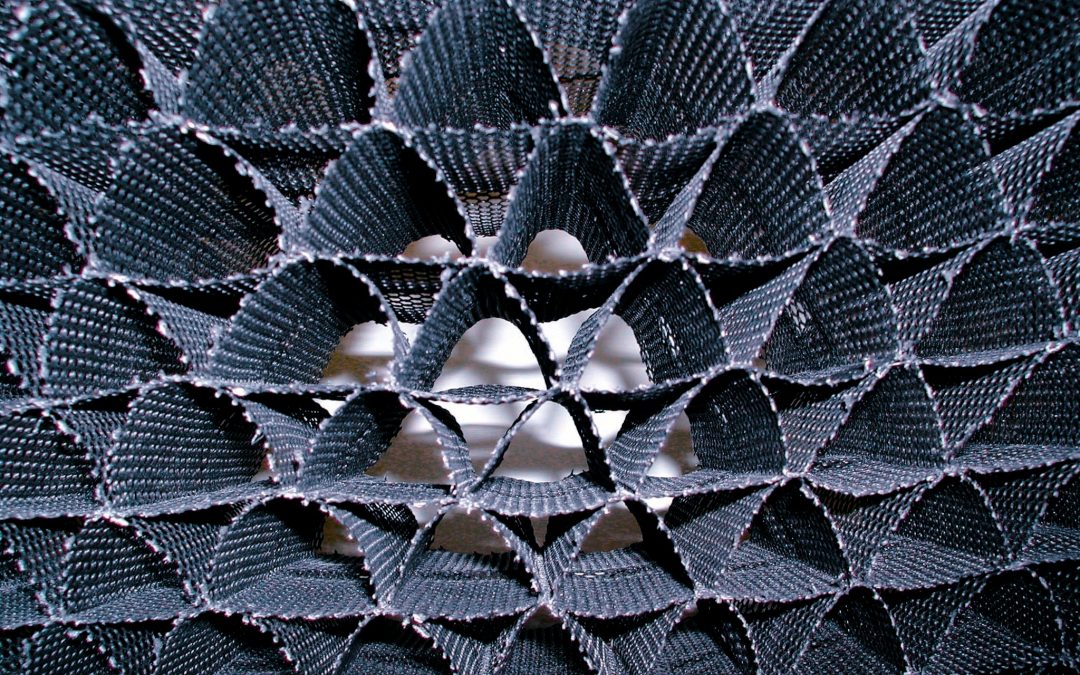

Control y Ventilacion, S.L. is a company of international renown within the industrial and livestock sector, for being a manufacturer of products within the evaporative cooling sector, such as the HUMIBAT, evaporative plastic cooler; or its NUCLEOS towers, Cooling Towers. In both products, the substrate in which the evaporative process is produced is a plastic honeycomb, a honeycomb resistant both to physical and chemical attacks, and at the same time flexible, a honeycomb with a mesh structure, made of polyethylene High Density, and marketed under the names of PANAL C & V or in the case of being a drop separator, SEPARADOR C & V .

For more information you can see the following links:

www.controlyventilacion.com/refrigeracion-evaporativa/

www.controlyventilacion.com/relleno-y-separador/

www.controlyventilacion.com/torres-de-refrigeracion/

Recent Comments