Cooling Tower

Cooling Tower

The equipment

The cooling tower is equipment designed for cooling water by direct contact with the environment. When air and water contact there is a sensible heat exchange, or heat transfer from water to air by temperature difference, and an exchange of latent heat, or moisture absorption of water by air to reach saturation (for each kg. of Evaporated water there are 542,4 Kcal absorbed).

The air properties that intervene in this process are temperature and it´s moisture grade, measured together with the air wet bulb temperature.

The cooling of the water in a cooling tower will depend on the difference between the temperatures of the hot water (input water), the wet temperature of the air, the quantity of air input to the tower, and, very important, the contact surface between the water and air, or interface core.

The main components of a cooling tower are: the fan, the filling and the water distribution, in addition to a high efficiency drift eliminator.

The parameters that define a tower are the wet bulb temperature, the water flow, or calorific power to evacuate, the thermal jump or difference between entry and exit water temperature, and the water temperature which is desired to exit from the tower.

Our ADVANTAGES

Our DIFFERENCES:

- Non blockable/ long life pad– Consistent performance

- Flexible plastic filling and very easy to replace (The

workman will appreciate it) - High efficiency drift eliminator (CERTIFIED)

- Easy cleaning

- Free of corrosion

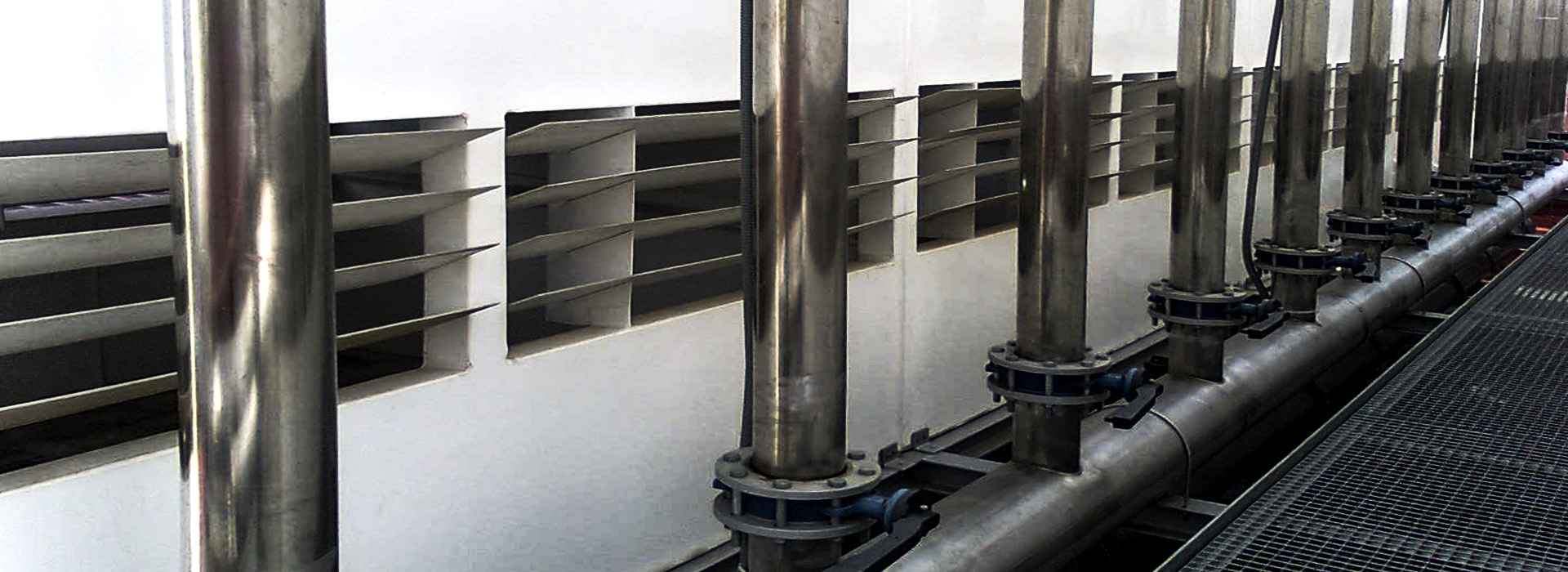

Núcleos de Interfase System

The cooling towers made by Control y Ventilación, S.L., under the trademark Núcleos de Interfase, are designed to have a long lifetime, both structural and mechanical, maintaining all its performances.

For this, the Núcleos de Interfase system incorporates hight quality materials and mechanical components. Reinforced polyester shell, high density polyethylene in the air contact body and polypropylene impeller axial fan.

The Núcleos de Interfase system incorporates a flexible polyethylene mesh in the contact body air-water as weel as in the drift eliminator, giving to the tower the following advantages :

- High density of contact surface air-water with a less aerodynamic resistance.

- High drop retention, giving a damp air and avoiding contamination problems (Certified by the Universidad Miguel Hernández).

- High capacity of solid deposit support or contaminants (lime, salt, dust, mud…) without any modification in the performance

In its construction, Control y ventilación manufactures two different types of towers. Giving placetwo different series:

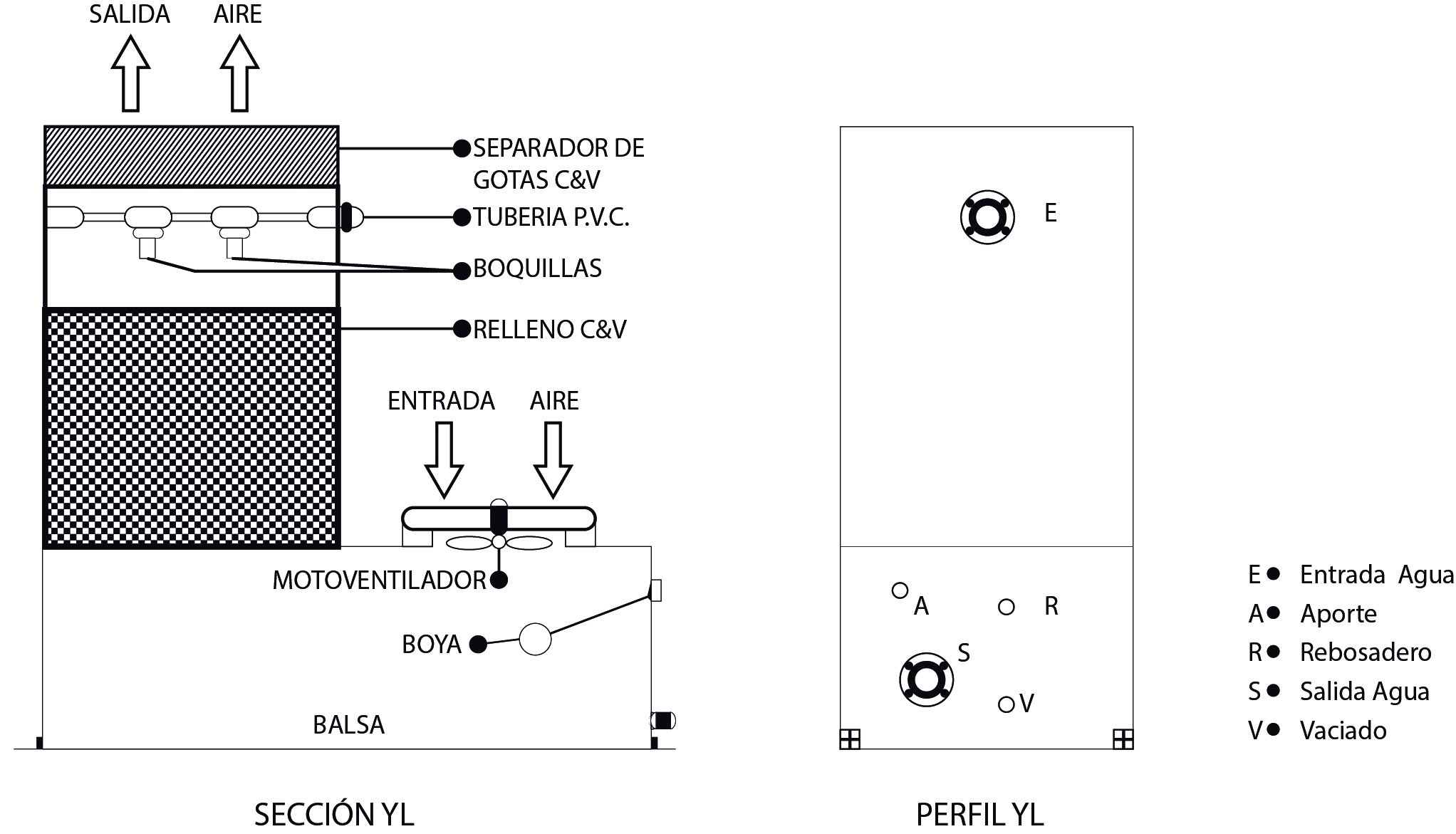

Serie YL

Formed by two coupled pieces with a simple support.

Its lower unit or water basin is elongated, giving to the tower an “L” shape. This allows, a large volume of water in circulation, also helps the access to the motor-driven fan which is situated in the water basin, supported by a stainless steel structure. The axial fan is connected directly to the axis of the motor.

The upper unit is the place where the thermal exchange happens; containing mounted filling blocks, the water distribution and the drift eliminator. Having the fan group in the lower part it offers an easy access for maintenance jobs in the upper unit (replacement and /or clean fill and drift eliminator)

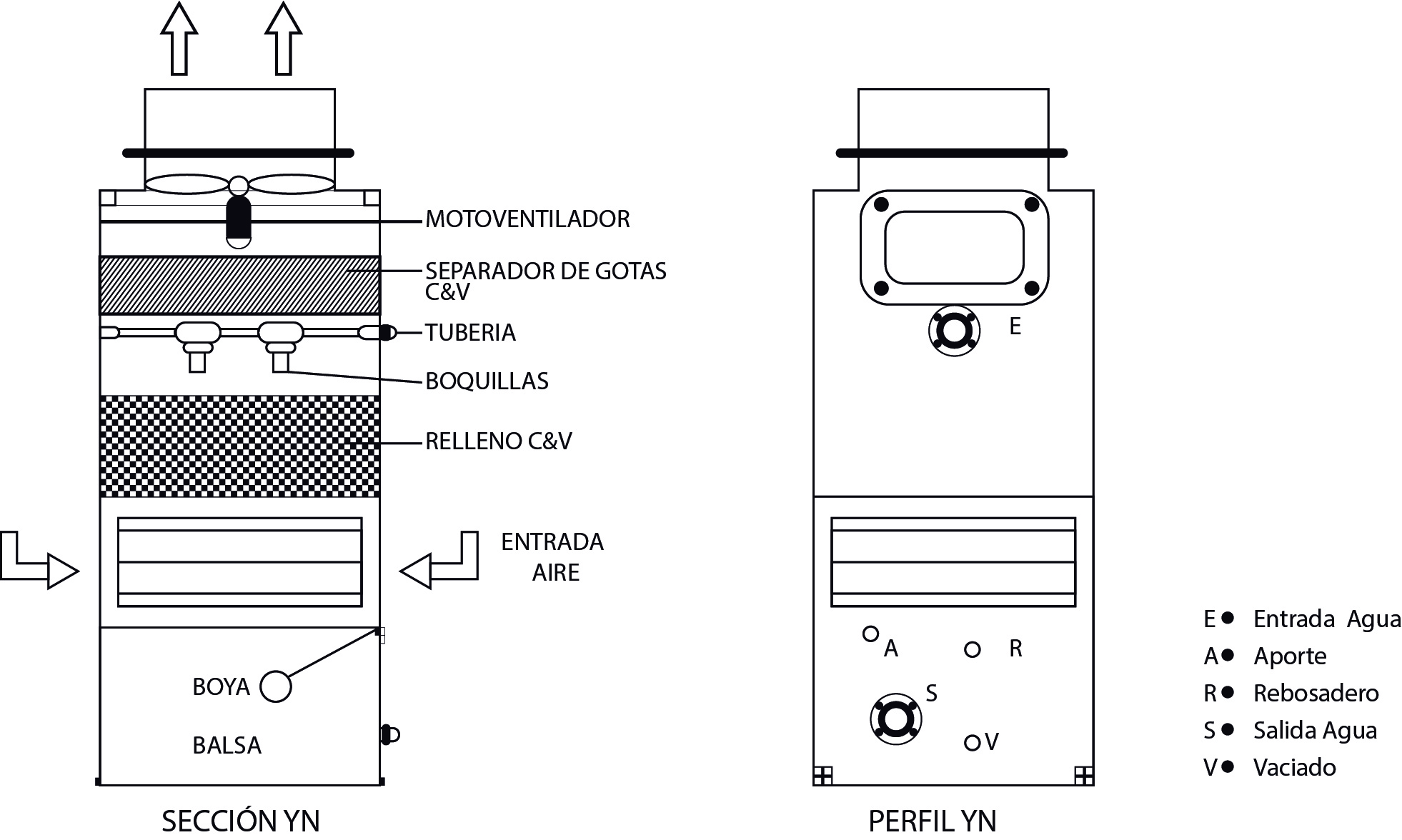

Serie YN

Formed by two pieces coupled with a simple support.

The lower unit that includes the water basin, also is the place where the thermal exchange , containing mounted filling blocks, and the air inlet.

Upper unit contains the drift eliminator and the fan group There is also a opening for maintenance and inspection purposes. The axial fan is connected directly to the axis of the motor, positioned horizontally fastened to the roof of the tower.