Filling and drift eliminator

Filling and drift eliminator

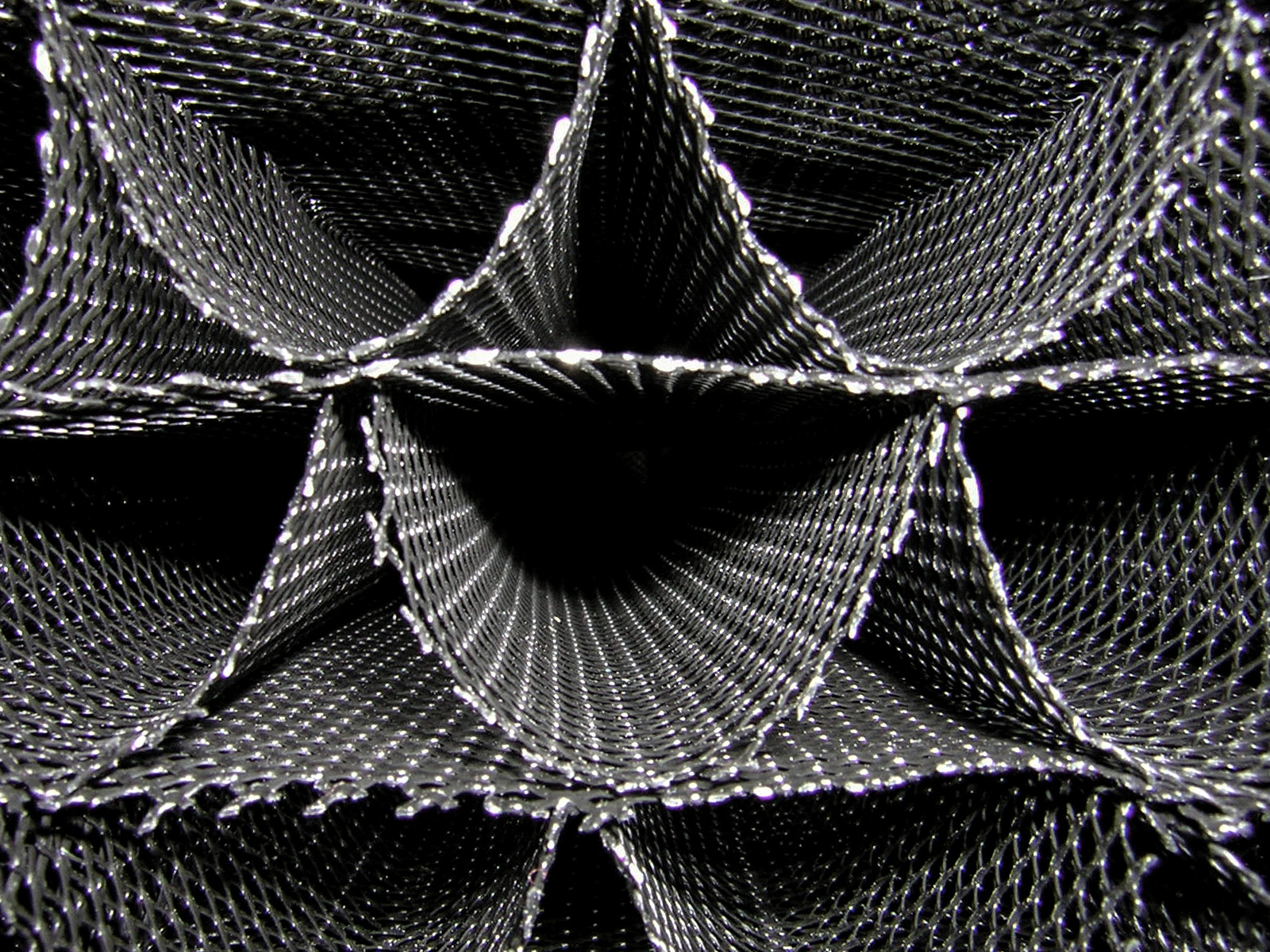

The pad

is a support to provide interface surface. So starting with this basic concept, it finds it’s activity field in applications related with the transfer of heat and mass between liquid and air.

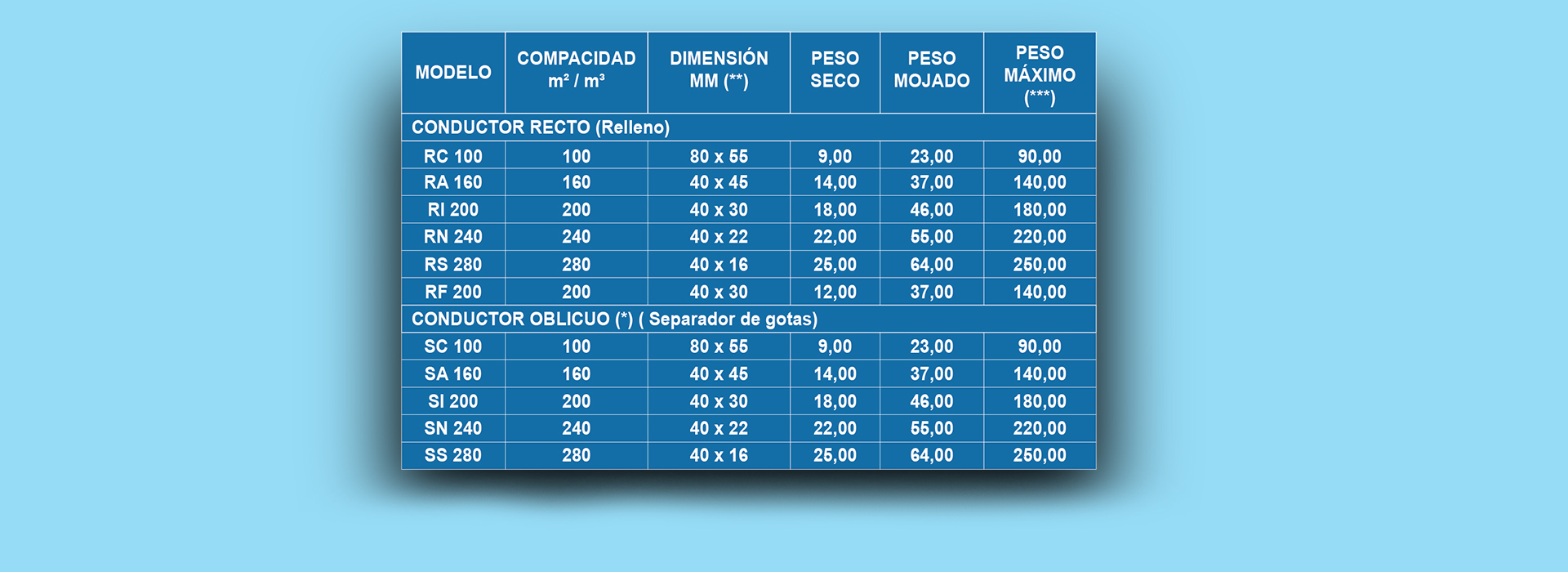

Depending to the obliquity of the canal in its constructive shape, Control y Ventilación manufactures and distributes its two large families of pads, the PANAL C&V (filling) with straight canal, and SEPARADOR C&V (drift eliminator) with an oblique canal, which adds to the qualities of the first one, an excellent high efficiency drift eliminator, for cooling towers and evaporative condensers.

SEPARADOR C&V:

The high efficiency of SEPARADOR C&V (drift eliminator)has been demonstrated and certified by the Miguel Hernandez University, specialist in this type of study which concludes that the water drag by the SEPARADOR C&V is the 0,00623 % of the circulating water from a cooling tower wich is about 8 times below the maximum allowed by law, which is 0,05% (R.D.865/2003)

CHARACTERISTICS:

- Thermal Efficiency

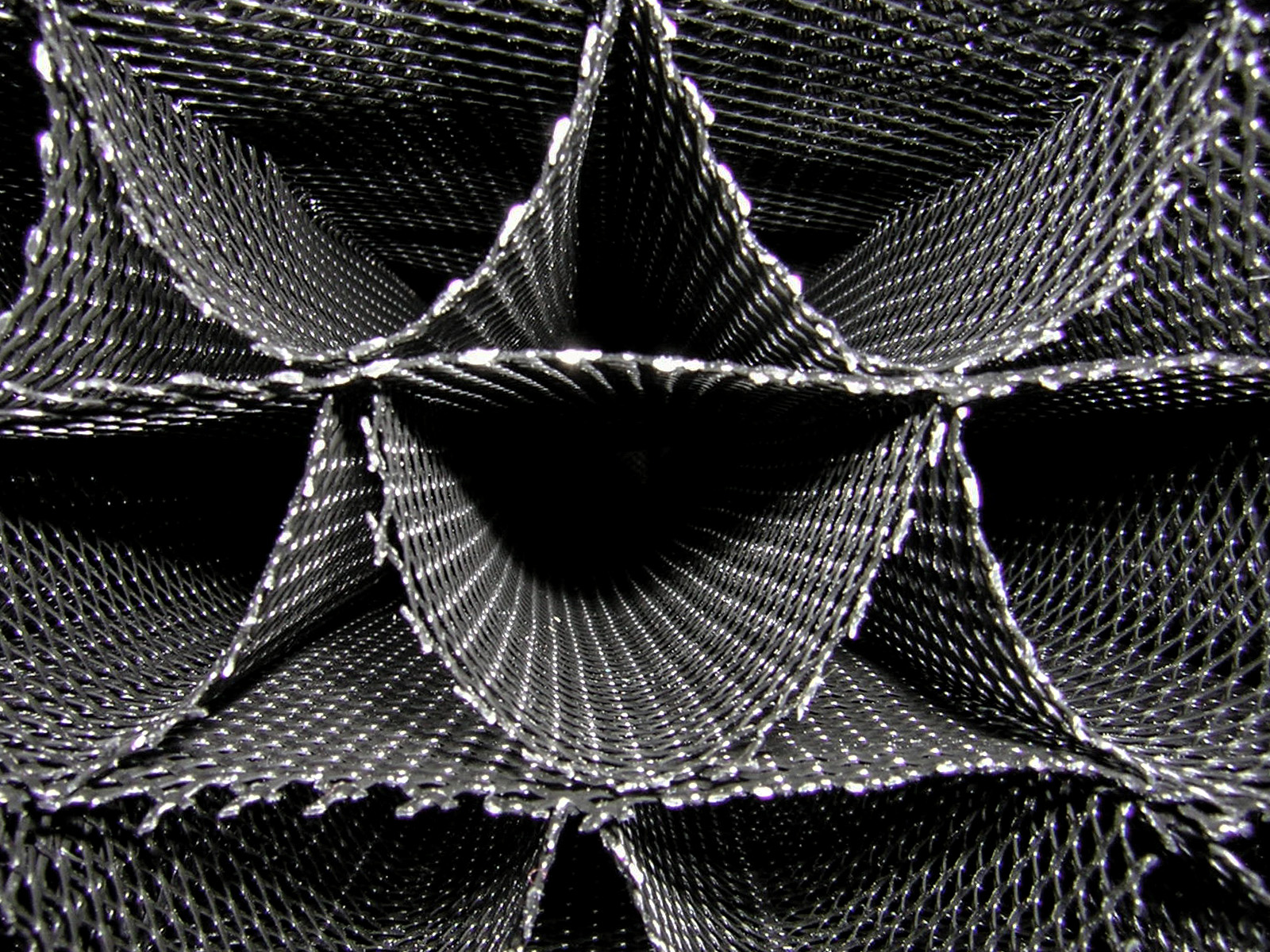

The use of the mesh in the construction allows to obtain a double contact surface, developing a total nominal interface liquid/air, wich allows greater thermal efficiency .

- AerodynamicProfile

The straight channel configuration of the pads helps the airflow, resulting in a low pressure drop .

- Mechanical stability

The specific resistance of the high density polyethylene mesh, as constructive feedstock, together with the channel stiffening effect it

gets by welding it, makes the pad present a total mechanical stability up to 75ºC.

- Resistance to the envyroment

High density polyethylene is one of the most chemical attack/resistant plastic materials.

- Easy Installation

The pads are light and flexible, they can easily be removed and replaced. They also offer the possibility to be cut to different sizes if is necessary.

- Minimum maintenance

The simple irrigation with high pressure water in many occasions will be enough to clean impurities. In extreme conditions, the pad resists the application of lime remover, with no alteration.

Our Advantages and our Differences:

- Flexible plastic filling

- Easy to replace ( the worker will appreciate this)

- It can adapt to any cooling tower

- CERTIFIED high effectiveness

FABRICATION:

Material

High density polyethylene (PEHD)mesh.

Assembly System, Automatic folding and heat sealing process, with a special triangular section form.

This way we obtain a prefabricated block or pad, in which the size of the triangular section can differ, providing the blocks with more or less compactness (interface surface per unit volume).

On the other side, the canals, wich are always straight, can either be parallel or oblique with respect to the airflow. The first form is used on machines with vertical air circulation, as cooling towers. While the pad with oblique canals also called drift eliminator, is used for retention of drop drag, and for machines with horizontal air flow, as evaporative cooling pads, air humidification sections for unit treatments, etc.