Given your interest we transcribe here the article published in the following link:

https://www.interempresas.net/Instaladores/Articulos/251190-Dos-anos-tras-la-revision-de-la-Norma-UNE-100030-sobre-legionela.html

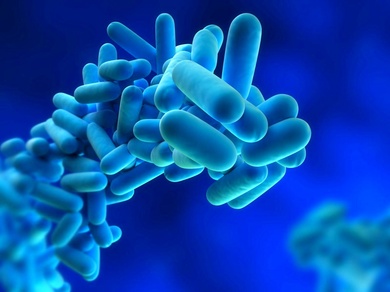

Two years after the revision of the UNE 100030 Legionella Standard

Two years after its revision and update, the UNE 100030 Standard, which establishes the legionella prevention and control framework, has demonstrated that its reform was necessary to adjust to the technical advances registered in evaporative cooling equipment – cooling three and capacitors. Its review essentially advanced in the classification of risk teams and in the prediction of the bacteria detection protocols, aspects in which, during these months, the main advances have been recorded.

New research fields

Following its review, the facilities contemplated by the UNE Standard were expanded as risk: cold drinking water (AFC), domestic hot water (ACS), cooling towers and evaporative condensers, humidifiers, humidifying plants and evaporative coolers, water heated with constant agitation (SPAs and hot tubs), ornamental fountains and urban sprinkler irrigation, nebulizers and others (for example, vehicle washing).

As a consequence, the inspections carried out by the health authorities, as well as the environmental and epidemiological investigations carried out on the occasion of the detection of cases of legionella, have been extended to all these teams, opening new fields in what to the investigation of the conditioning and epidemiological factors that cause such cases is referred to.

Security Increase

This extensive list of facilities in which the bacterium is capable of proliferating and spreading, allows, in addition, to provide the Standard with an exhaustive classification, beyond the classic division between high or low risk equipment, lacking scientific rigor.

In addition, facilities have been incorporated that, according to the experience of recent years, have caused some of the most harmful outbreaks in Spain. Likewise, the fact of including, for the first time, the humidifiers used in terraces and bars in the standard as equipment susceptible to control, provides greater security for citizens.

Improvement of action protocols

The reform of the Standard affected mainly aspects directly related to prevention, detection and action against the legionella, actions that, as a whole, have resulted in an increase in security.

In this sense, everything related to the collection and transport of samples, microbiological and physiochemical tests, alternative methods to the culture for the detection and quantification of legionella in the samples, and the generation of reports were insisted.

Rapid legionella detection techniques have allowed data to be obtained with great immediacy – just two hours – and act accordingly. Socio-sanitary security has been increased and expenses have been reduced, to the extent that, as disinfectant treatments can be initiated more quickly, it is no longer necessary to close the tower.

Other improvements

Finally, the update of the Standard allowed the elimination of the mandatory minimum distance between the place where equipment and human beings are located, in exchange for the development of more complete facilities, equipped with drop separators, which increase safety .

Likewise, the legionella levels to begin to carry out actions according to the new Standard are now at 1,000 CFU / l, compared to the 100 CFU / l of the previous one, a very common level in any water accumulation, which forced many unnecessary performances. This measure is positive because it allows to perform justified actions when there is an abnormal increase in the presence of bacteria in the equipment.

The Group of Manufacturers of Evaporative Cooling Equipment of Aefyt (Spanish Association of Cold and its Technologies) collaborated in the revision of the Standard, which came to light in 2017. The reform was not only focused on the incorporation of all facilities susceptible to develop legionella, as well as in the improvement of the aspects focused on the prevention and control of the bacteria, but also in other points such as the importance of the training and technical solvency of the personnel in charge of the installation.

Control y Ventilacion, S.L. is a company of international renown within the industrial and livestock sector, for being a manufacturer of products within the evaporative cooling sector, such as the HUMIBAT, evaporative plastic cooler; or its NUCLEOS towers, Cooling Towers. In both products, the substrate in which the evaporative process is produced is a plastic honeycomb, a honeycomb resistant both to physical and chemical attacks, and at the same time flexible, a honeycomb with a mesh structure, made of polyethylene High Density, and marketed under the names of PANAL C & V or in the case of being a drop separator, SEPARADOR C & V .

For more information you can see the following links:

www.controlyventilacion.com/refrigeracion-evaporativa/

www.controlyventilacion.com/relleno-y-separador/

Recent Comments